Hi Guys! I've missed you! As usual, my summer is filled with fun, life sized activities that leave less time for minis. And the time that I do find is comprised of short stretches of work that leave my progress (and my chronicling of it) fragmented. As I begin to assemble my photos to recreate the story of my progress, I am a bit weary of how well I can make it flow. Please bear with me as I try!

I believe I last left off with trying to finish up the trunkhouse's first floor living room. I had made a mess applying Paperclay between the timbers and needed to sand and touch up the paint. I've done that and managed to get a very rustic look. Here is where the room stands today. It is ready for window frames and ceiling.

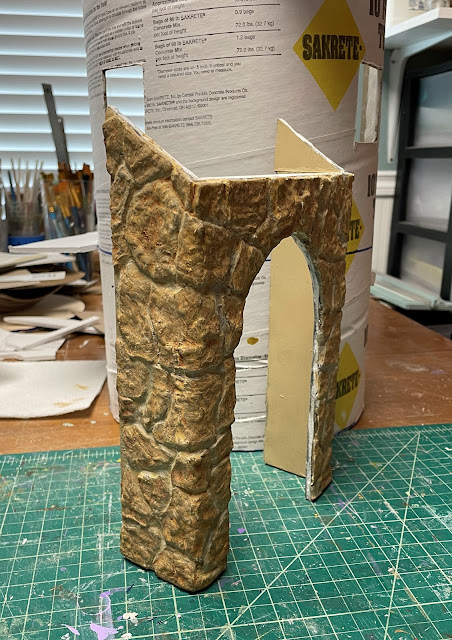

I stopped there to begin getting the small entry/front door attachment sorted out. To refresh your memory, it is made up of a foam core floor, walls and roof, and will have a fairy shaped door.

To the walls, I've added "stones" just like the wood stove hearth.

|

The floor is covered in wooden floorboards to keep it simple. Part of them will show on the "porch", and part of them will show inside.

|

| With Fred's Weathering Stain applied. |

I can't be sure if the underside of the porch will be exposed after I apply all the bark, so just in case, I finished it with deck boards and wood beams.

|

| After staining. |

The ceiling/roof were finished similarly, with a rough wood ceiling and a standing seam "metal" roof. Beams and paint to come...

I said I wanted to cut a window in the fairy door and I did, Then, I made an interior and exterior window frame out of a couple laser cut Tudor style windows that I had in my stash. In the photo below, it is hard to see that the door is painted in a satin purple paint called wisteria and that the window frames are painted in a contrasting, sparkly metallic paint called Amethyst. It is a nice contrast and, hopefully, will show up better in later photos. I have yet to "glass", embellish and install them, but hope to this week.

In the photos below, I have all the stones applied, sealed, grouted, age washed, sealed again and the door frame installed.

In this photo, I have installed the timbers and applied the Paperclay inside. Though a little cleaner job, I still have a bit of touch up to do.

But not until after I get all the moss applied into the exterior stone's crevasses.

With a little luck and some quieter days, my next post will have better continuity. Maybe the first floor living room might even be completed! I know Roz and the gang will be delighted to reach that milestone!

Until then, my friends, work on making your mini dreams come true. Even if tiny piece by tiny piece!

xo xo,

Jodi