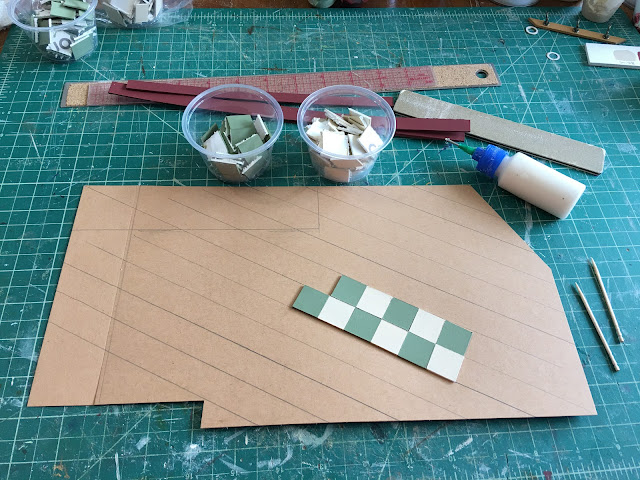

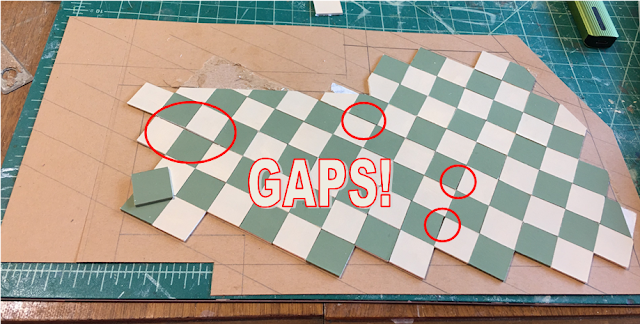

You know how it took me a couple tries to get the floor tiles "right"? Compared to other things I'm working on, only two tries seems lucky! For the Willowcrest's wee kitchen chairs, ultimately, I wasn't satisfied until the seventh try!

The first thing I needed to do was to get a feel for 1930's and 1940's kitchen furniture styles. I perused Google and collected the photos of tables and chairs that just spoke "vintage" to me. There were things I liked about each of these pieces in the photo below, and using the knowledge, tools and materials I have available to me, I thought I could probably come up with something close.

Once I had a picture in my mind of the features I liked in the chairs, I needed to get some measurements. I brought out several of the chairs in my stash so I could get a feel for size. The chair on the left is Town Square Miniatures, the one in the center is Chrysnbon and the one on the right is House Of Miniatures. What it demonstrated is that the size of mini furniture varies widely. As long as the seat height was pretty close to the standard, around 1-1/2", the rest of the design could be fitted to my space and table.

|

| If there are any James Bond fans reading this, you may laugh or cringe at the cane seat being removed from the middle chair. Casino Royale was the movie. Le Chiffre was the perpetrator. OUCH!!! |

Next, I turned to Tinkercad where I could create a design, print it out, assemble it and then make incremental improvements until I ended up with something that fit my criteria. I wanted a chair design which produced a consistent print quality, that assembled easily, and looked similar to many of the 30's and 40's style chairs that I liked. Most important, it had to be cute! I love the double arch design, and it just goes so great with all the other arches in the Willowcrest!

|

| Many iterations and assembly configurations to test. |

|

| The final design. |

Now that the design and print process were good, it was time to compare my chair to the others in my stash. I eliminated the HOM right off because it was noticeably tinier. But compared to the Chrysnbon and the Town Square chairs, mine worked!

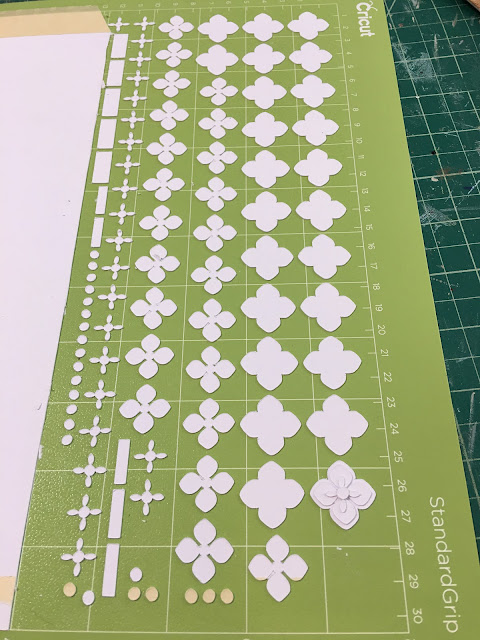

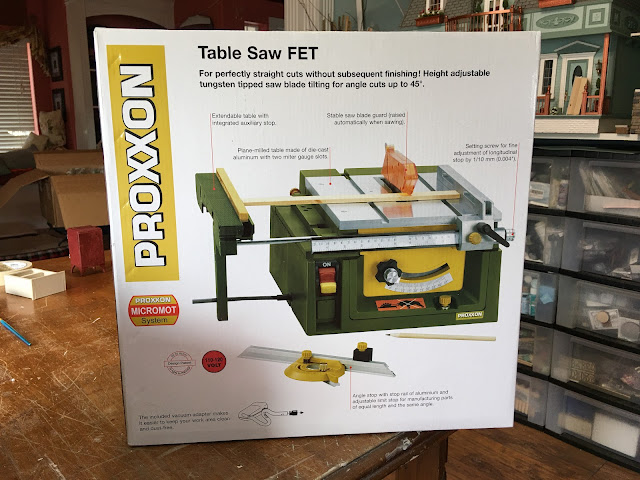

While my trusty X-Max was printing many chairs (at just over 2 hours each), I was working on the table. I decided to design the table in Design Space and cut it from chipboard with the Cricut Maker.

I was so engrossed in the table's assembly process that I forgot to take photos! Essentially, the table is comprised of a chipboard box which holds two working drawers on either side and a "porcelain enamel tabletop". This was a common material for that era, and I really loved the look. I made trim pieces to overlay the chipboard from kraft cardstock to add a layer of art deco detail. I combined several graphics to create the tabletop design, then used the Print Then Cut feature in Design Space to cut it from regular printer paper.. The table legs are standard Houseworks legs that I had in my stash. I painted the table elements in a mixture of the kitchen's colors, and applied the graphic to the table top with Mod Podge. I did not brush Mod Podge on top if the graphic because of the way it made the wallpaper's printer ink smudge previously. Instead, I spray sealed it with satin varnish. It shows wear on the drawer fronts, and might get a little more scuffed as I age the kitchen cabinets. The most pleasant surprise was that I only had to make the table once!

I used an amalgamation of 30's-40's table measurements I found online, and also factored in the space I had to work with in the Willowcrest kitchen. Here is how it worked with the test chairs, and then with my chair.

I really like the vintage feel and it works as well as you can hope for in this compact little kitchen!

The chairs definitely need some "cushy for the tushy", so I'll make the cushions when it's time to dress the room. For now, it's still too hot to wallpaper, so my mini time will be spent on the PC. At least here, I can sit in front of my Hot Flash fan and design the accessories for my little home cook. I have some fun stuff to share with you next week!

Hope you're finding ways to stay comfortable while working on your projects, too!

xo xo,

Jodi