This week in Tasha's Kitchen the focus was on the tile backsplash, crown molding for the cabinets, window trim and making a gas cooktop.

Although I had purchased an Elf Miniatures Gas Hob Stove Top Kit, I looked online for inspiration. I was thinking it might be a fun endeavor to try to make one instead. This was my inspiration photo...

Easy right? Well, maybe not easy, but if you have a 3D printer, thanks to a generous Mother's Day gift from the very daughter you are making this kitchen for, it's a heck of a lot more feasible. So, I started in TinkerCad, working up a design that could eventually look close to my inspiration photo. I made a six burner model and included separate components such as the gas burners, the grates, a frame to house them in and some teeny control knobs.

Now the big test! How did it work in the space? Amazing!

To make the base, I used a 2" x 3" piece of 1/16" basswood then glued a 3/16" trim piece on the front. I covered that with craft aluminum, bending it around the front so that it looks like a solid stainless steel cooktop.

I had originally painted the 3D printed parts with regular acrylic paint. I was not very happy with the finish, so the next day I printed a new set of parts and this time painted with a Posca Paint Marker. It came out much smoother and actually looks like cast iron!

|

| First Try Using Acrylic Paint |

|

| Second Try Using Posca Paint Marker |

And then I printed them two more times until I got all of the little adjustments right. Each time it took nearly four hours to print.

When it was finished, I set about painting the parts with the Posca markers, then sealed them with a matte spray sealer.

|

| The tray piece will be lined with aluminum, so only the edges get painted. |

I cut a piece of aluminum for the front panel with enough extra to bend around the front and a piece to lay inside the tray. I used Aleene's The Ultimate Glue to adhere the aluminum to the PLA.

Once the adhesive had a good grip, I scored the aluminum and gently bent it over the edge.

I applied the adhesive to the back of a piece of aluminum for the tray and to the bottom of the tray itself. After a few minutes I joined them together.

To attach all of the other components, I used 5 Minute Epoxy.

To make sure the gas burners would be aligned correctly, I set the grates in place...

I marked the center with a Sharpie and then removed the grates.

I placed a small amount of epoxy on the bottom of each of the four legs of each grate and set them into place. The legs hold the grates up at just the right height above the gas flame (theoretically).

I measured, marked and applied the epoxy for the control knobs next.

Ta-da! A gas cooktop! In the photos below I have just set it on top of the mini fridge unit to give you an idea what it looks like on the top of a countertop.

Here you see the first built in version with the basswood base (right) and the new 'all inclusive' countertop version (left) side by side. The great news is that the second model can be utilized whichever way your project calls for. I'd call my endeavor to create a gas cooktop a rewarding success! What do you think?

If you are interested in obtaining a gas cooktop for your project, either assembled or in kit form, Click Here.

In the meantime, while the cooktop components were printing, I kept busy on the backsplash. I mentioned in last week's post that I was using the same MDF brick sheet that I had used in the New Orleans kitchen (and bathroom). It comes as a 5" x 9" sheet and has the brick pattern etched into it. I was only able to source the Streets Ahead brand from a dealer in the UK this time. I was a little surprised to see that the bricks were a little bit larger than the Houseworks brand that I got last time. They were still going to work fine, as there is a lot of variation in real life tile sizes.

|

| Here I have done the bottom four rows. The upper rows show the defect. |

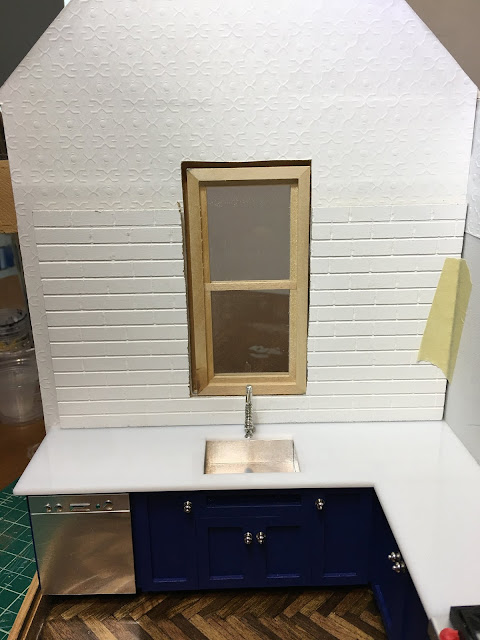

I only had to cut the sheets down by 1/8" to fit the wall space on both walls. I painted them with white acrylic paint, sanding any brush lines smooth after each coat had dried. After a final dry fit, I was able to cut out the window opening in the sink side piece with my jigsaw.

I added trim to the edges of the tile sheets and around the top of the window opening to make an even surface for the window trim. I checked the final fit with the cabinet in place. All good! Now I could finish painting and sand one last time.

|

| Ready for the high gloss coating! |

I sprayed a couple heavy coats of Krylon Triple Thick and then let the panels dry for several days before attempting to install them. I did not want to ruin all of my dedicated work by getting a fingerprint in the finish! It's hard to capture the sheen, but they are very shiny and smooth just like porcelain tiles. The best thing about using this type of tile with this method is: NO GROUT! Yippee! Who else loathes having to grout due to a disastrously bad past experience? 🙋♀️

While the tile panels were curing (and while I was waiting for the cooktop parts to finish), I worked on crown molding for the upper cabinets and the wet bar. It's amazing how such a little detail can add so much style to the look of a cabinet!

And then finally, it was time to install the tile panels!

And then the china cabinet cupboard and window trim.

Just for Marilyn D. and Sherrill, a better view out the kitchen window. Cherry blossoms are just around the corner, and they are so much nicer a view than a bunch of paintbrushes!

Please look past the rough and unpainted sashes. That part of the construction is still in the queue!

Next week, I hope to bring the kitchen into mini house code compliance by adding an extractor fan, attaching the right wall, and maybe even raising the roof! A lofty bunch of goals, I know, but this kitchen is practically building itself!

Have a wonderful week, my friends, and Happy Spring! For those of you in the other hemisphere, I hope you are just as excited to welcome a nice, cool fall!

xo xo,

Jodi