This week I received an email with an exciting and challenging request! A fellow mini enthusiast is the lucky owner of the Majestic Mansions Park Avenue dollhouse kit. She is planning to pay homage to the movie Breakfast At Tiffany's by recreating a close resemblance to the famous facade. She's asked me to do my best to replicate the arched doorway pediment, trim and corbels. Those are a job for the 3D printer, but the main and basement doors, which she has also requested, will be a job for the Cricut Maker. This will be the most complicated design and print work I've taken on, so far, and it is so thrilling!

|

| Park Avenue Kit and Breakfast at Tiffany's Brownstone |

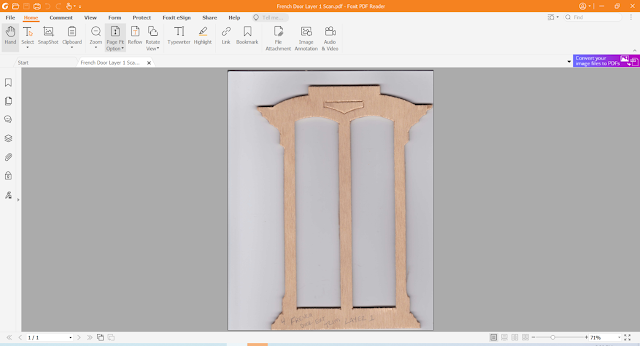

Because I am a novice at 3D designing, my knowledge is limited to Tinkercad and what I can do with it's basic library of shapes. Luckily, there are a host of web sites like Thingiverse, Cults, and others. Some designers offer their amazing .stl files for free! Once the files are downloaded, I can import them into Tinkercad. I turned to DavidG7 for his excellent and generous leaf corbels, and was able to figure out the rest of the pediment and frame with Tinkercad's shapes. It's helpful when searching if you know what architectural term is used for what. I had to bone up on them!

I know if you haven't ever taken any time to play in Tinkercad, it's hard to believe that with just four basic shapes, two free corbels and a free fig leaf you could make historic looking architecture for your dollhouse in about five hours. But I swear it's true! I encourage all of you to go have a play and see what you can make! You may just be putting a 3D printer on your Christmas or Hanukkah wish lists!

|

| Square hole, square, half circle, pyramid, free corbels and fig leaf. |

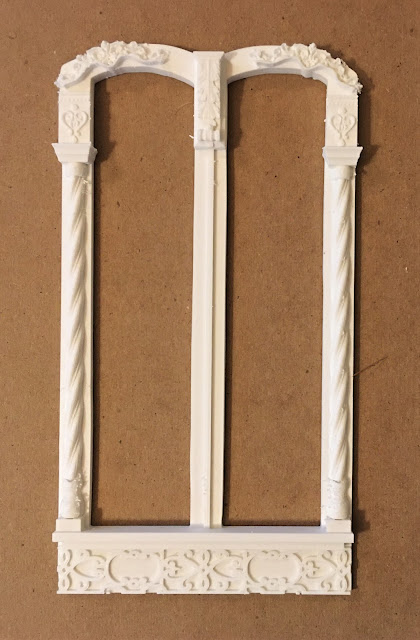

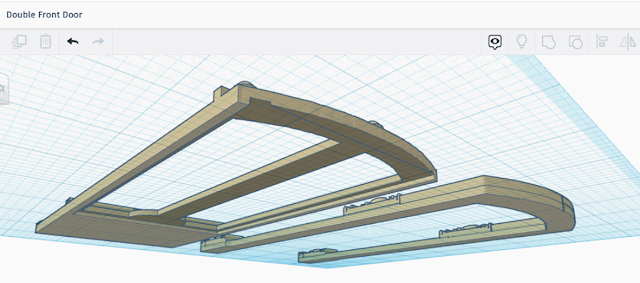

Here's what the assembled pediment and doorframe trim will look like.

|

| 8" tall x 5-1/16" wide x 1-1/8" deep. |

Close up detail.

Side detail. The real test will come when it's time to print.

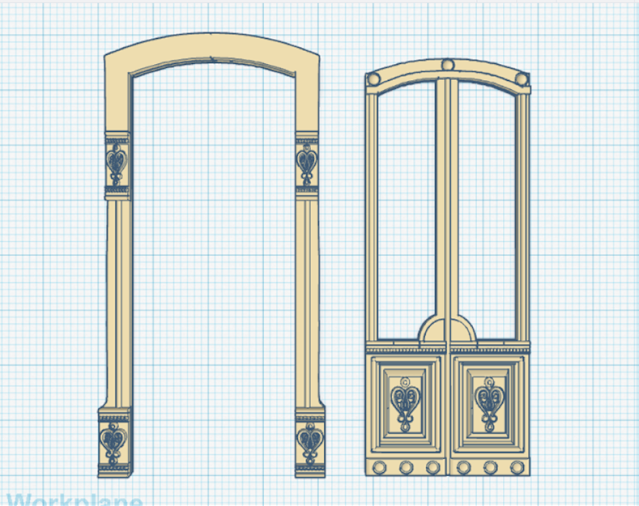

One of the challenges we miniaturists face is trying to work with the space we've got while still replicating the look of real life homes. This was especially challenging here because the real life BAT doorway is so much larger than the doorway on the kit. The ceilings in the BAT house are 12 feet high so the windows and doors are huge. The doorway opening is around 11 feet. I'd need an 11 inch opening to create a true replica in 1/12th scale. In the kit, the ceilings are only about 8". I had a 7" doorway opening to work with (4" less!), and then there was only 2-5/8" to the bottom of the window opening above. With these limitations, I am unable to create a true replica that still allows a 5.5" dollhouse doll to fit through the doorway without looking like a giant. But with what I had to work with. my results are pretty stellar!

Here's the real life version and my effort side by side.

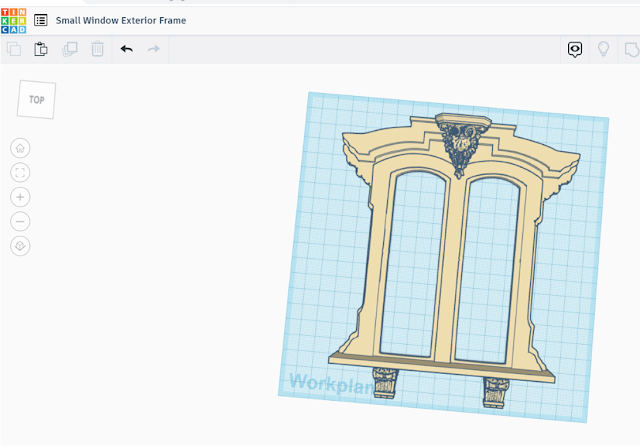

The customer is also considering having me design replacement windows to look more like the BAT house. The challenge here is that the kit window openings are much, much slimmer than the real life windows. It takes space to make a curve, and the openings for the windows are square. Ideally, you'd cut rounded window openings and then create chipboard frames. But a lot of us don't yet possess the skill or the tools to fulfill all our dreams exactly. Adding a curved pediment to the tops of the frames might just give a close enough resemblance to the look she wants.

|

1 9/16″Wide by 5 1/16″High = about half as wide in scale. |

That's about all I had time for this week. Dad left today to make his way back home to Arizona. I feel so lucky that I got to spend time with him in person twice this summer - once to kick it off and once to finish it. Enjoy the first days of fall! I'll be back next week with who knows what!

xo xo,

Jodi