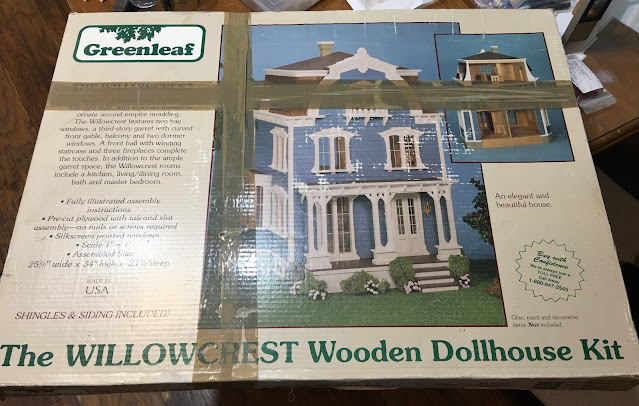

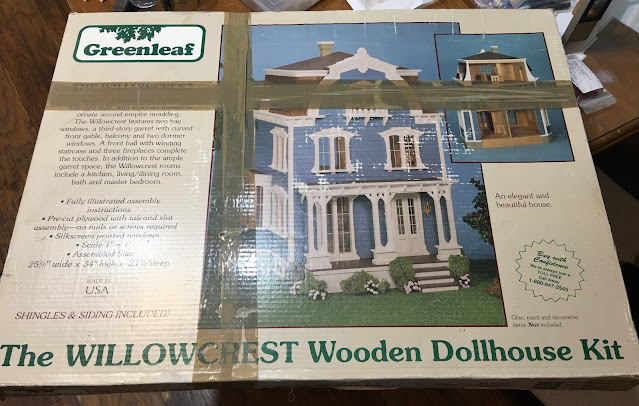

One of the dollhouses that has always been on my bucket list is the Willowcrest. Unfortunately, the kits (made of 1/8" tab and slot plywood) were discontinued by Greenleaf sometime after the last release in 2009. I didn't get back into minis until 2012, so I thought I may have lost my opportunity forever. I've always kept my eye out for one, but whenever I saw them, they were way over my comfort price for a dollhouse kit. There are currently four of them on eBay ranging from $375 to $450, not including the pricy shipping. And they don't guarantee the condition or completeness. Yep - way out of my comfort zone. Farewell sweet dream...

And then... You know how when you make a wish, sometimes the universe conspires to make it come true for you? Well, imagine my surprise when, randomly, a Willowcrest kit showed up in my Facebook Marketplace feed! It was located less than an hour from me, it was the same price as the last release price in 2009, and it was brand new! Sort of. The nice man who sold it to me was selling it for his sister, who, received the kit from her parents back in the 1990's. She's a busy mom now and has no hope of ever having the time to build it. No problem! It'll be going to a good home - mine!

When I opened the box, everything looked to be there and was in amazingly good shape. You can imagine how delighted I was when I confirmed that every sheet was accounted for, and at least topically, in tact. There was even a brand new set of Houseworks door knobs in the box. Bonus! They aren't pictured here, but the instructions, schematics, warm up sheet, Greenleaf Guarantee sheet and catalog were also inside and in perfect condition. ✅

I really didn't want to start another big project, as I was enjoying the regular endorphin rush of completing my many "almost finished" projects this year. But you know how the miniaturists' mind works: let me just look at the instructions, let me just punch out a few pieces to see the wood's condition, let me just do a quick dry fit, let me just take some notes and make some plans for the future. Um hum. You know where this is heading. I'm alternating now between groaning "What Have I Done?" and extreme excitement.

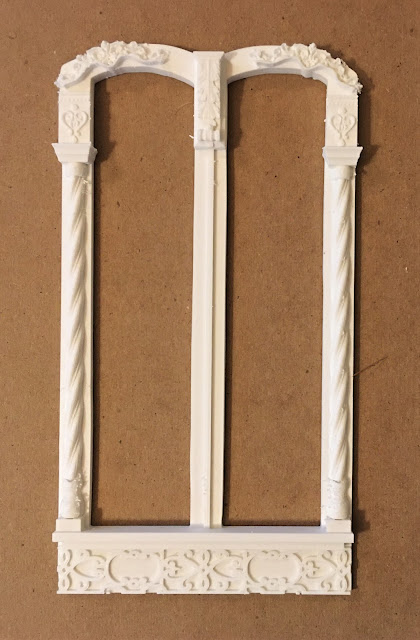

|

| Punched, primed and dry fit the pieces from the first page of the instructions. |

I had a talk with myself. I said "Okay, so we're doing this now. Accept it and get to work!". I spent the first few days scouring the internet to see what those who've gone before me have done. There is so much inspiration! The kit definitely has a few awkward and challenging spaces along with it's uniquely beautiful Second Empire features. Many have tweaked the design or added on to gain square footage and maximize the usable space. The very best example of thinking totally outside the box and hitting a home run with the kit is blogland's very own Elizabeth at Studio E! Her Villa Leone, which is set in Venice, is astonishingly beautiful and extraordinarily creative! Fittingly, it won Best in Show at the Vancouver, Canada mini show!

I am not that ambitious with my plans, though I can't help but want to make a few improvements and use a few of my technology tools to see what can be done. To that end, I began with the room that, by all accounts, they recommend you start with: the entry/stairwell that spans both the first and second floors. This is because it quickly becomes inaccessible, so it's a build/decorate/build situation.

|

| Kitchen, front, looking into the entryway/stairwell room. |

|

| Looking thru the front door opening into the entry/stairwell room. |

|

| Spiral stairwell's left corner. |

|

Looking thru the front door opening you can

go straight into the kitchen or left to the living room. |

That meant I had to make some decisions right away. I often begin a project by finding an inspiring paper pack, and that's exactly what I did here. I wanted to do something totally different than any of my other projects, and kind of in keeping with Second Empire style. I chose the Stamperia Grand Hotel paper pack as my theme. My Willowcrest wanted a very romantic and old fashioned kind of feel, but because I am a die hard Laura Ashley fan, I'm going to mix many patterns and colors using these scrapbook papers as inspiration.

Next, I assembled the staircase. This was so that I could get it measured against the kit's right (looking at the front) wall. You see, I want the first and second floor entry/hall to be seen as much as is possible. It's a grand space, probably the best space in the kit because it's mysterious. It really ought to be appreciated! The kit comes with a very tiny (and cute) diamond square window, and the upstairs landing can be seen through the front window, but viewing into those areas is extremely limited.

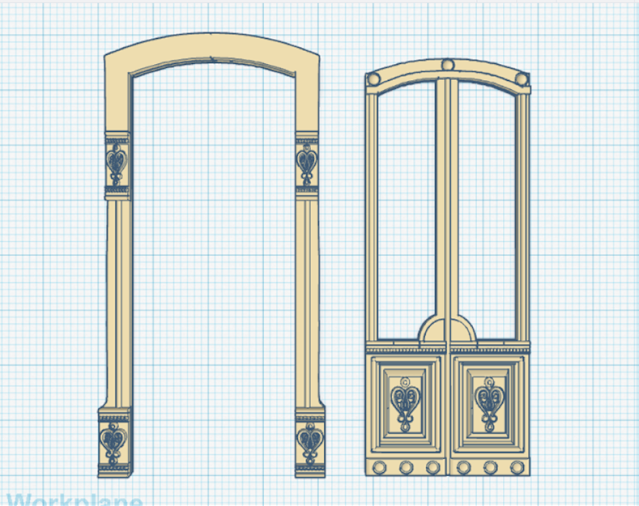

After the stairs had been minimally constructed, I was able to mark up the main stairwell wall to plan for a much bigger window. In keeping with the kit's design elements, I decided to use the French Door window (from the first floor adjacent to the front door) as my template.

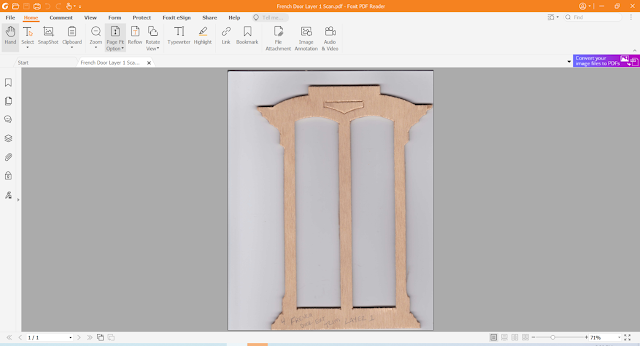

|

| French Door Ext. Layer #2 of 4 |

Here is the interior layer of that frame traced onto the stairwell wall...

And with the stairs taped in place...

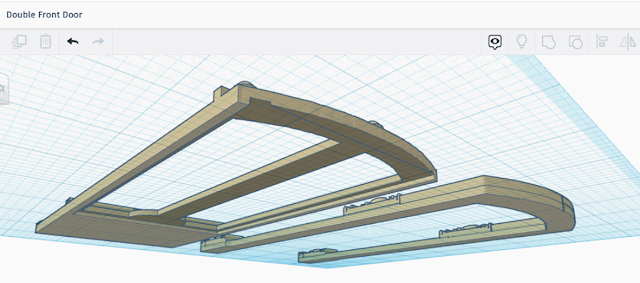

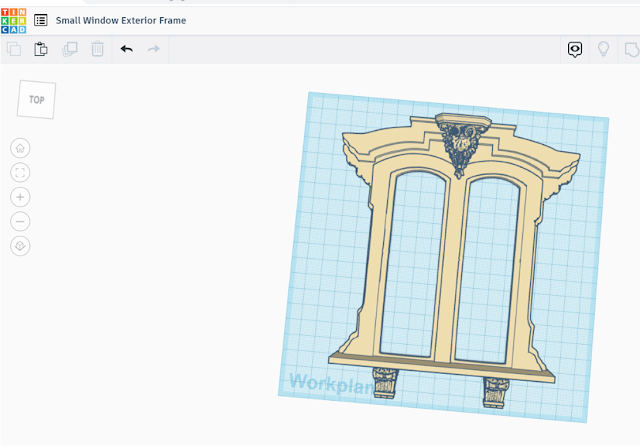

But how can I replicate the fancy, multi-layer and double arched interior and exterior frames? Technology - that's how! I'll even attempt to make them fancier! Details to follow in my next post.

Although it will probably take a very long time to accomplish this bucket list Willowcrest dollhouse, I am really going to enjoy it no matter how long it takes. I hope you'll come along on the journey, and I hope it inspires you to make a wish!