One of the things I am okay with admitting is that I am either completely board with something, or completely obsessed with it. Enter 3D modeling and printing...

I was watching the first season of House Of Cards with my husband the other night (we are starting with the first season so we can binge watch the other seasons on a lazy, rainy weekend), and I kept noticing all of the incredible set decor. Things like lamps and headboards. Suddenly I am designing them in my head and not even paying attention to the show! Thank goodness for the rewind button!

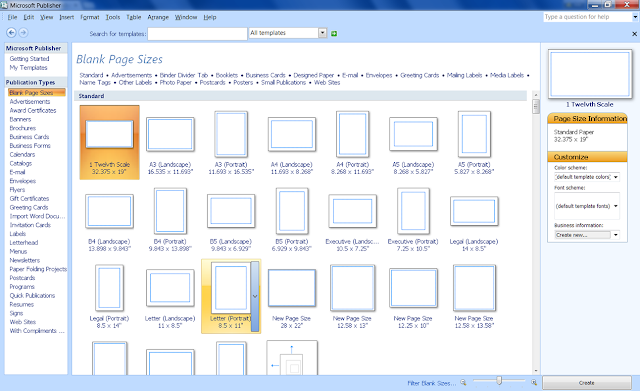

I'd been watching quite a few tutorials on SkillShare lately. One was by Lauren Slowik from Shapeways. It was interesting, but the way she went about creating and uploading the image wasn't going to work for me. My subscription to PhotoShop has expired, and I am still really on the fence about committing again when I rarely ever use it. Anyway, to make a long story a bit shorter, I just signed up with TinkerCad (it's free) and started playing with shapes. I can design with shapes - I really don't need to do much sketching on paper, so this was perfect!

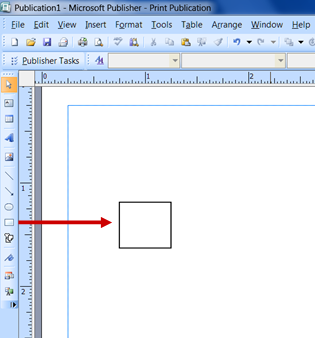

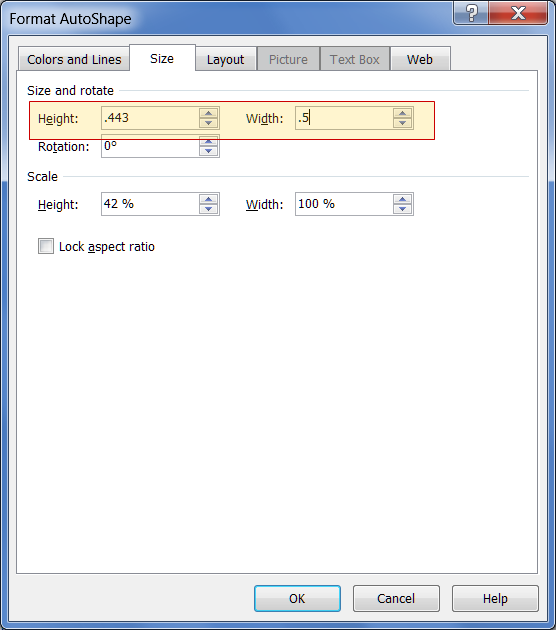

I'd been watching quite a few tutorials on SkillShare lately. One was by Lauren Slowik from Shapeways. It was interesting, but the way she went about creating and uploading the image wasn't going to work for me. My subscription to PhotoShop has expired, and I am still really on the fence about committing again when I rarely ever use it. Anyway, to make a long story a bit shorter, I just signed up with TinkerCad (it's free) and started playing with shapes. I can design with shapes - I really don't need to do much sketching on paper, so this was perfect!I started by Googling some real life sized lamp measurements, then converting them to 1:12 scale. Then I took some of the ideas in my head and quickly drew them on paper, just so I wouldn't forget. I converted the measurements to millimeters, then began to "doodle" in TinkerCad.

I just so happened to have a 1:12th lamp shade with a built in 12v standard bulb/socket holder. It was easy to use the dimensions in my lamp and base designs. They should perfectly cradle the bulbs and support the shades. I made all of the bases hollow and made cord exits on the bases. I have finished a couple lamps so far, and I have drawings for a couple more. Once I am finished, I'll order them and see it they actually do work the way I planned! If so, maybe I'll try a couple headboards!

I just so happened to have a 1:12th lamp shade with a built in 12v standard bulb/socket holder. It was easy to use the dimensions in my lamp and base designs. They should perfectly cradle the bulbs and support the shades. I made all of the bases hollow and made cord exits on the bases. I have finished a couple lamps so far, and I have drawings for a couple more. Once I am finished, I'll order them and see it they actually do work the way I planned! If so, maybe I'll try a couple headboards! See! Obsessed with 3D printing! Meanwhile, the barn sits among my messes on the dining room table, just waiting until I am no longer board with it. As soon as I am not, I will become obsessed with it again.

See! Obsessed with 3D printing! Meanwhile, the barn sits among my messes on the dining room table, just waiting until I am no longer board with it. As soon as I am not, I will become obsessed with it again.

Oh! By the way... I went and retrieved Enoch. He was hiding behind some trees waiting for campfire stories to begin. I talked him into letting me repair his loose leg. Poor guy! That must have hurt!

While he was recovering, he and Gerdy chatted up a storm. They have become fast friends, and Enoch agreed to carry her wherever she needs to go. Must be tough when arthritis sets in and you can't straighten your legs out any more.

I guess we all have some flaws.

Have a great weekend, everyone!